I. Drive System Optimization: Improving Efficiency from the Source Adopting a Permanent Magnet Synchronous Motor (PMSM): Replacing the traditional asynchronous motor, this results in higher efficiency during variable speed operation and a 10%-20% re...

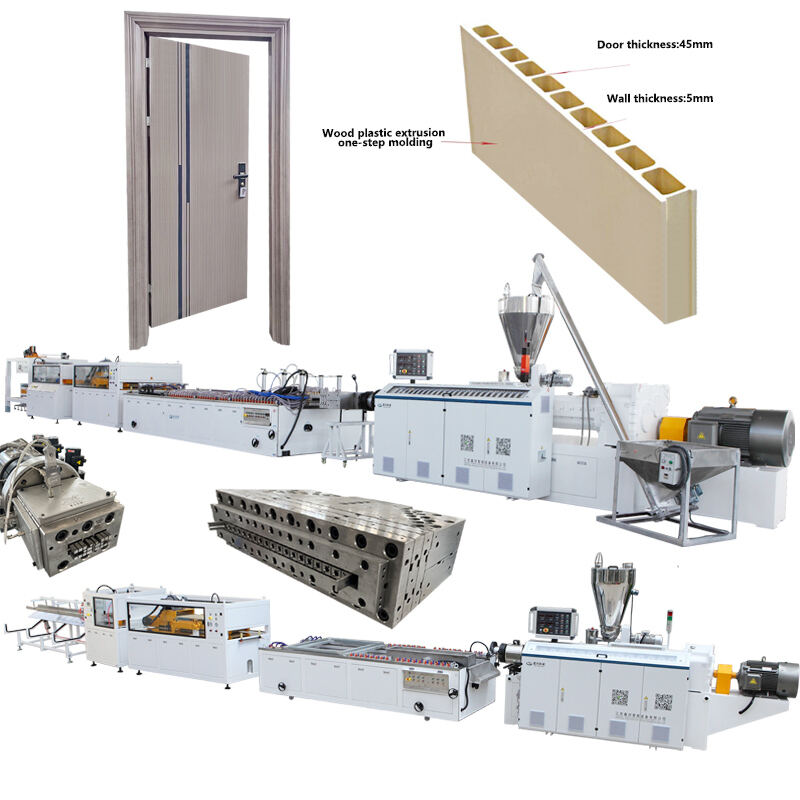

In the WPC door panel extrusion molding process, temperature control is a key factor in ensuring product quality. The temperature control system precisely adjusts the temperature of each heating zone of the extruder and the hot die, and controls the ...

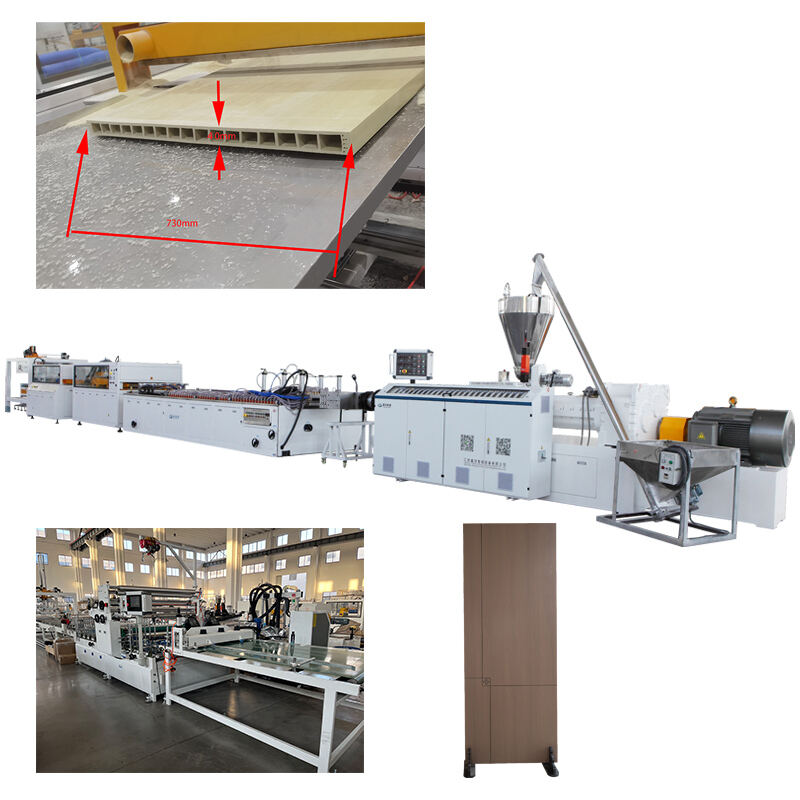

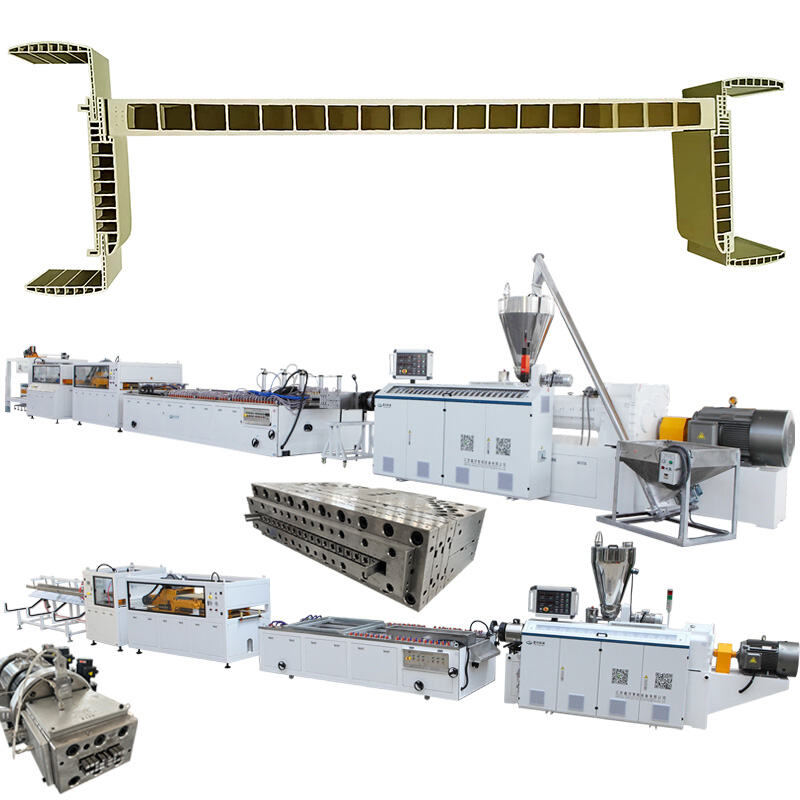

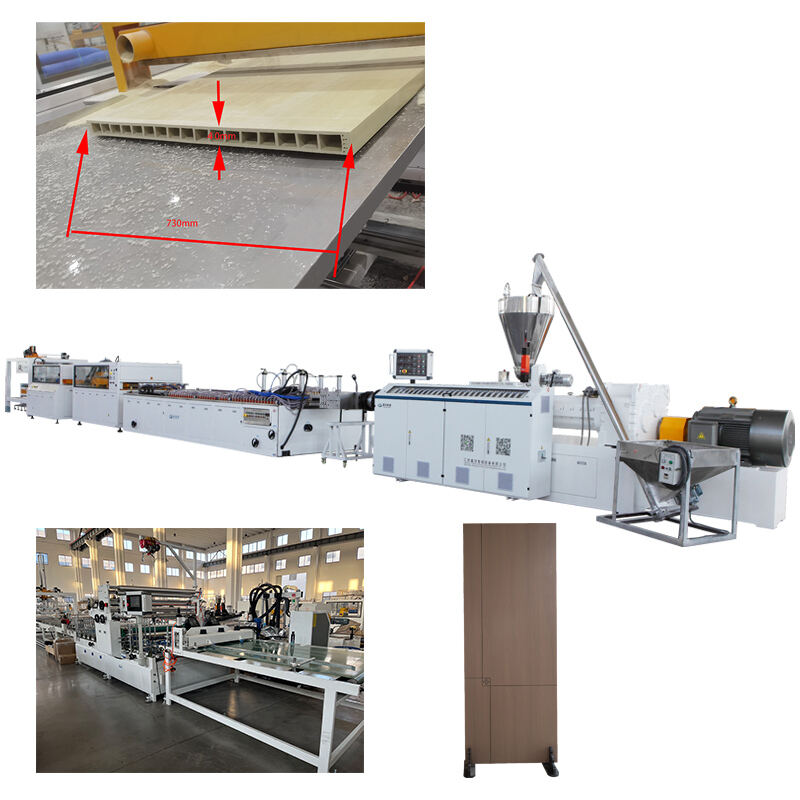

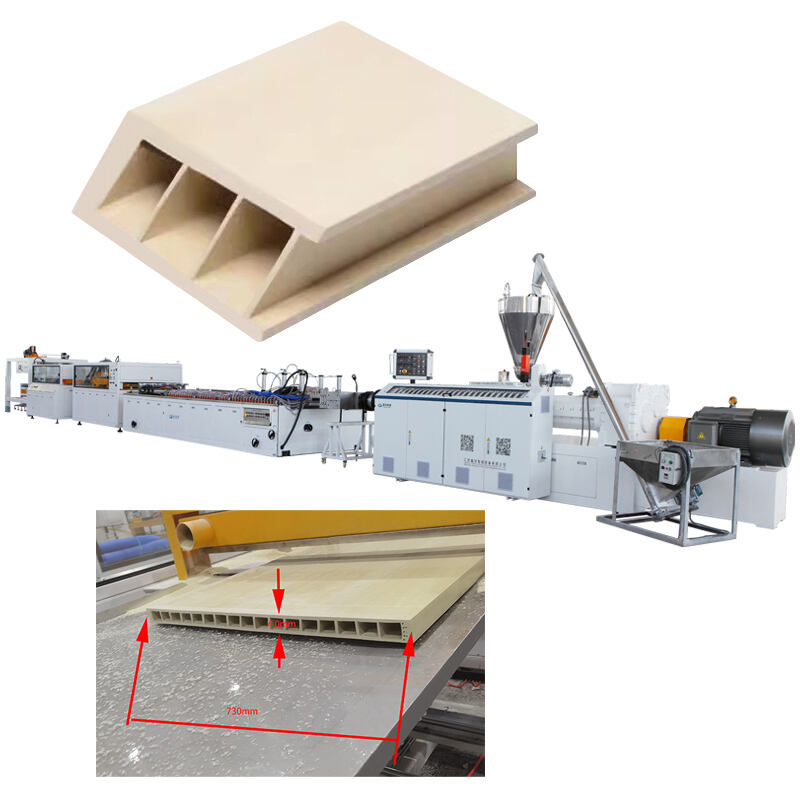

The working principle of a WPC door panel extruder is actually an automated closed-loop process from raw materials to finished products. Xinhe Machinery helps you understand it clearly: I. Core Process in Three Steps 1. Raw Material Mixing: PVC granu...

Xinhe Machinery has actual door panel manufacturing clients in countries such as Saudi Arabia, Vietnam, Jordan, and Iraq. We provide technical support from raw materials to finished products, helping clients grow from zero to over a dozen door panel ...

WPC doors (wood-plastic composite doors), as a representative of green building materials, are ushering in unprecedented development opportunities. Their core advantages lie in their environmental friendliness (raw materials are mostly recycled plast...

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy